dPIPE 5.28

1. Fixed bugs:

- Printout of the assessment of the supports reactions vs permissible loads is blocked for parts of model marked as boundary conditions. This inconsistency has occurred during THA;

- Printing of accelerations for valves evaluated according to NP-068 has been restored when viewing results in PIPE3DV;

- An error has been fixed that prevented entering the coefficient of transverse weld for pipe sections as a text label (FW2 = 'AUS'/'CS'/'CMV'). This specification is allowed for analyses according to Russian Code RD 10-249-98 and for high-temperature piping calculated according to PNAE Code;

- An error causing program termination when attempting to change the section in the DDE table has been fixed;

- An error preventing data saving when changing beam section parameters has been fixed;

- The "Lock during HTEST" function has been restored for group operations on spring hangers and supports;

- The procedure for finding maximum forces in dampers for multiple dynamic load cases (RULE = 'MAX') has been adjusted: the maximum is now determined for the total horizontal and vertical components, not separately for each component.

2. New options and additions:

- two tables with Seonghwa (Korea) springs have been added to the sh.dbs file: the 'SEONGHWA' table with travel of 50-100-200-300-400 (mm), and the 'SNGH_ADD' table with travel of 80-160-240 mm;

- a table for Hesterberg (2022 catalog) springs has been added (file sh.dbs);

- a check for the presence of specifications has been added to permissible loads on supports using tables from the database. If the specification is missing, a warning message is displayed.

- the output format for one-component supports in printout tables has been changed. In the result printout, information has been added about the coordinate system in which the support is defined and the loads are displayed. For more details, please refer to the help-file, Appendix II.

- the printing of resulting tables for expansion joints and tables with loads on valve’s nozzles has been unlocked when the OUT = 'NO' flag is present in LS with the type "FORC".

- for spring supports/hangers, which are interpreted by the program as "boundary conditions," the "flashing" effect when viewing results in PIPE3DV has been blocked.

3. Changes in DDE GUI:

- the functionality to save user-defined selections of parts of piping model with the option to reload the saved sets of selected sections during and after work session has been implemented, (watch video );

- the change of the line thickness is implemented when piping model is displayed in 1D: the line thickness is adjustable in the "Options - Graphics" dialog.

- the option to insert an intermediate node into bend element has been implememnted for the graphical mode of the data entering;

- in the "coloring" mode, the option to change colors has been added. To do this, one needs to double click on the legend with the mouse.

- In the graphics input mode, the functionality of moving of existing node on a certain distance from either another node or the point of intersection of tangent lines to a bend has been added, (watch video );

- An option to measure distances from a given node to the point of intersection of the tangents to the bend has been added

dPIPE Utils

4. PIPE3DV:

- user-defined selection of the parts of piping model is saved between sessions;

- the view of the deformed state for beam elements in 3D is fixed;

- the view of one-component one-sided supports located on a vertical run is fixed ;

- the location of the local axes of the element has been changed: now the local coordinate system is displayed not in the node, but in the center of the element

5. CVSpec-TH:

- the issue of losing accuracy when importing data from another program into time histories has been resolved. The increment by the step size has been replaced with the calculation of time values at each step;

- In the functionality of renaming a group of records (CTRL-H), an option to consider or ignore letter case has been added;

- the determination of the sampling interval of the accelerogram has been fixed when exporting data from a *.dat file (a text file with two columns of "time - acceleration"). Previously, the sampling interval was calculated as DT = T(2) - T(1), and now it is DT = (T(NT) - T(1))/(NT - 1), where NT is the number of rows in the *.dat file, and T(1), T(2),..., T(NT) are the time values in the corresponding rows;

- since the response spectra calculation algorithms in CVSpec-TH assume a constant sampling interval of the input accelerograms, a check for the variability of the sampling interval has been introduced. If the variability exceeds a specified threshold (default threshold is 3%), a corresponding message is displayed, and the file is not added to the project. The threshold value can be adjusted in the "Settings" dialog;

- a folder ADDONS with auxiliary programs has been added to the program's installation folder, which allows for adjusting records with variable sampling intervals through interpolation of the accelerogram data. Detailed instructions can be found in the "lint_v.readme.txt" file included in the folder

dPIPE

- 1. An option "drug and drop" for the insertion of "extra data" into the nodes of the calculation model is implemented (https://youtu.be/3C0cXwD8EyU)

- 2. Fixed procedure for automatic meshing of the model when inserting a tee joint in the node: a new node merges with the previous one if the distance between them is less than the minimum length of the element (see the EL_LEN parameter in the CTRL command)

- 3. The functionality for the insertion of a new node and breaking a branch with the help of Graph Input tools is added for rigid element. Editing of the rigid element may be done by double mouse click with CTRL key

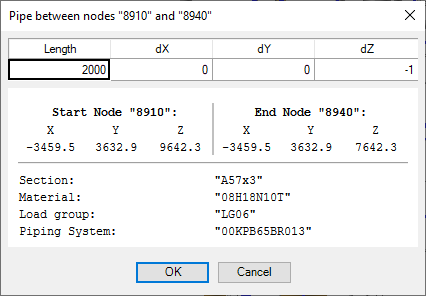

- 4. For a "straight pipe" and rigid link elements, information about the element is added to the quick edit dialog. This dialog is called by double-clicking the left mouse button for a straight pipe, or by double-clicking the left mouse button with CTRL for a rigid element

- 5. Fixed error resetting the load group parameters when editing elements

- 6. The change of directions after BEND/MITER elements is blocked for the next element

- 7. The situation when the thickness of the branch appeared less than the thickness of the matched pipe was changed from an error to the warning

- 8. Display of the support under the valve's body is fixed

- 9. Fixed program crash when copying and pasting a piping section with a FLEX element

- 10. Display of seismic groups of supports is fixed

- 11. A scaling of additional data when displaying the analysis model in one line is blocked

- 12. Fixed program crash when inserting a force into the node

dPIPE

New Analysis Options:

1. Provisions of new Code is implemented in the program: non-mandatory Appendix A "Alternative method for stress analysis of piping" from GOST R 59115.15-2021 “Justification of Strength of Equipment and Pipelines of Nuclear Power Plants. Calculation of strength of typical pipeline units”. Generally, this document repeats requirements and approaches of the PNAE, but has some differences. Accordingly, the following changes have been introduced into the program:

- equations for allowable stresses are harmonized with new strength criteria installed by GOST R 59115.9-2021 “Justification of Strength of Equipment and Pipelines of Nuclear Power Plants. Calculation of strength”;

- fatigue curves used in analysis are calculated based on temperature-dependent specific material properties. See Appendix XVII of the help file for details;

- the requirement to fulfill the shakedown criterion (SRK stress) is now mandatory;

- coefficients used for calculation of temperature stresses due to gross structural discontinuity or material discontinuity are revised

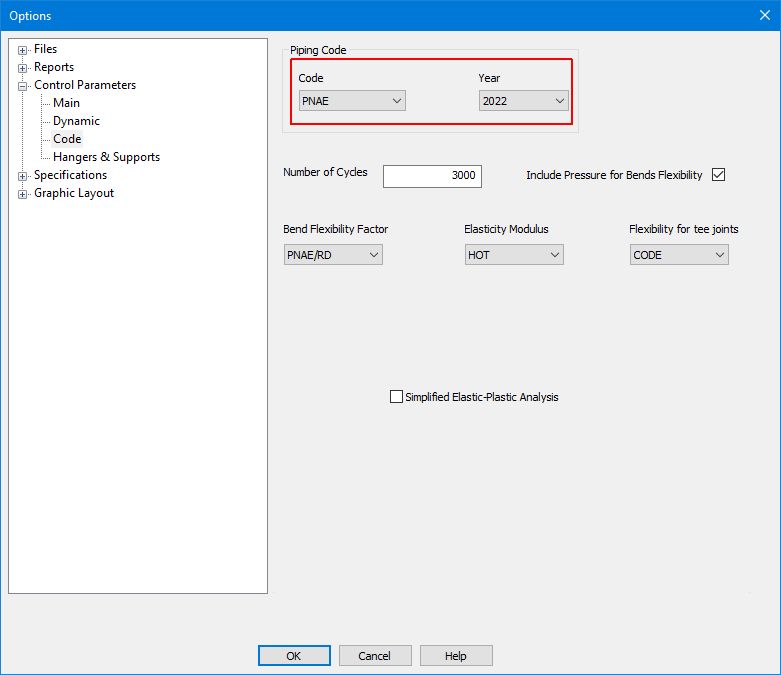

The following options under the CTRL command set analysis according this CODE:

CODE = 'PNAE', CODE_YEAR = 2022:

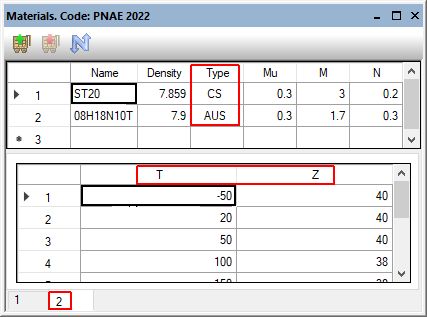

Additional parameters required for calculation of fatigue curves are added in the Material Properties: material type and reduction of area Z:

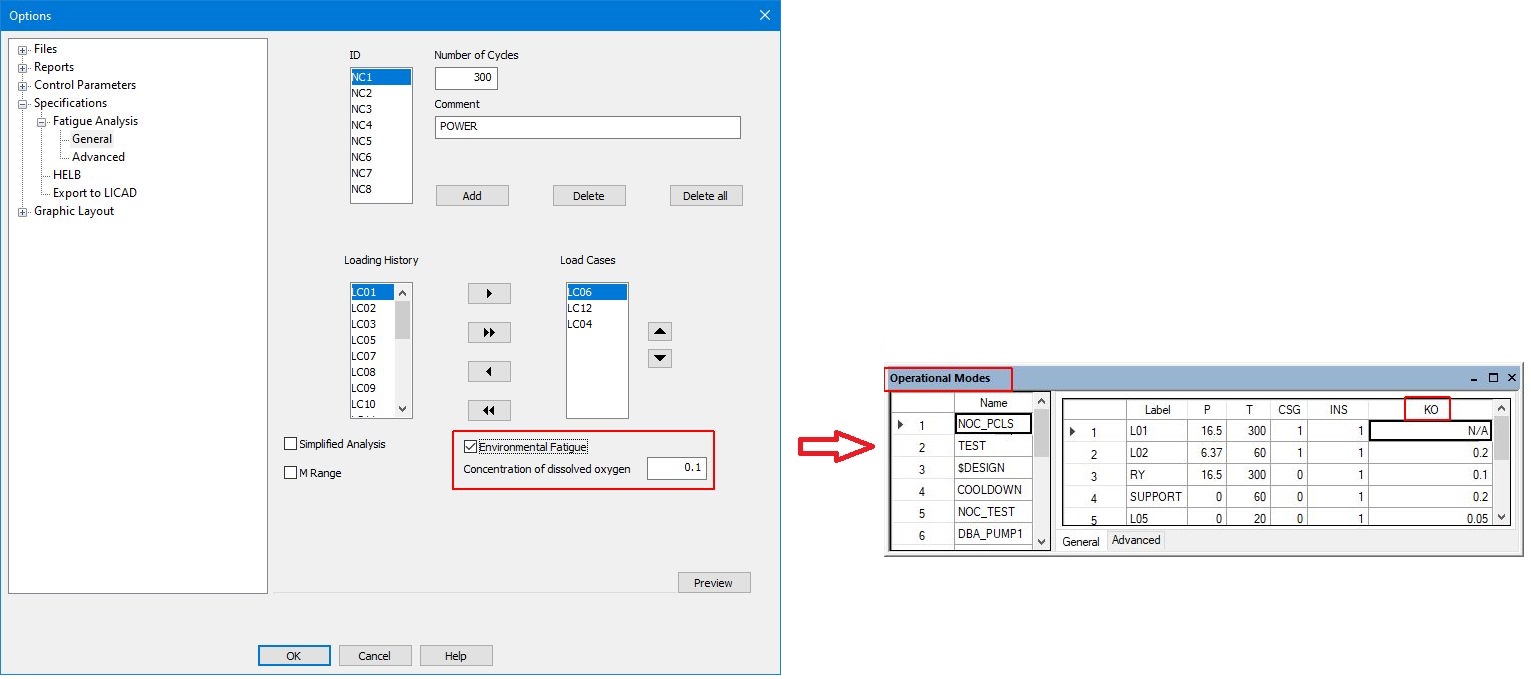

These new data are already added in the “mat.dbs” file. Apart of that, for the environmental fatigue analysis an additional field “KO” is added in the “Operational modes” input window. KO stands for water oxidation in milligram per kilogram and is defined with help of new ENVFAT command. The column with KO becomes available for editing providing the option “Concentration of dissolved oxygen” in the fatigue analysis specification is activated.

2. Accelerations of the valve’s body and actuator are printed in results (*.sup file) individually for each dynamic load case, (watch video ).

3. Realization of High Energy Line Break (HELB) procedure for PNAE Code is upgraded. Added adaptation of this procedure for EN 13480, see Appendix XVIII of the help file.

4. The data for spring hangers design from Hesterberg catalogue is added in the sh.dbs file

User Interface Changes:

5. Elements of graphical input of the piping model are added in User Interface:

- Drawing of straight pipes, (watch video )

- Insertion of Bends/Elbows along branch, (watch video )

- Insertion of intermediate nodes, (watch video )

- Split the branch to insert support with option CNODE, (watch video )

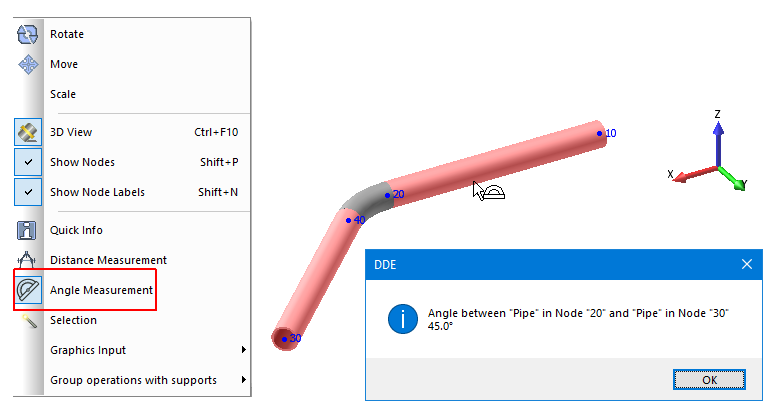

6. The functionality of measuring angles between piping sections has been added to the program interface

7. The weight of the selected piping segment may be calculated with new command, (watch video ).

8. An incorrect assignment of a seismic category to piping elements generated by automatic FE meshing has been fixed (applicable for PNAE analysis)

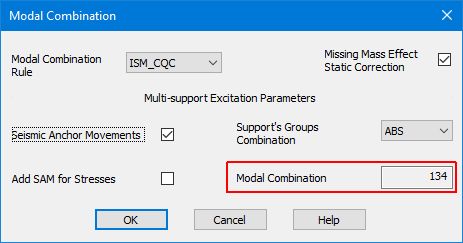

9. The numerical value of MCOM option for modal combination is visible now in the dialogue window:

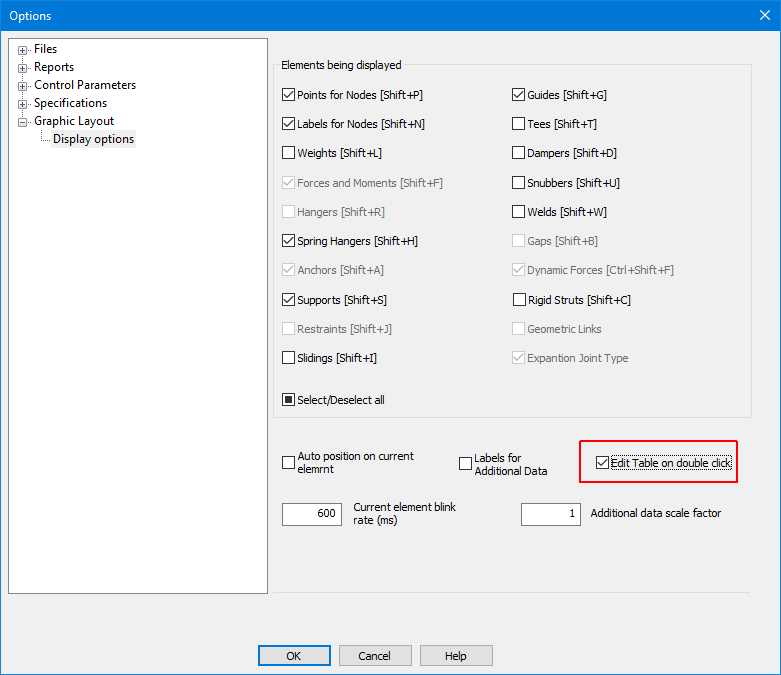

10. An option “Edit table on double click” is added in the “Display options” tab. Its activation allows to avoid the "beep" system signal when one double-clicks on the fields in the "Additional data", "Section" and "Group" columns of the "Geometry" table."

11. Displaying of the damper located on the vertical piping run in 3d view is fixed: it is shifted relative to the axis of the pipe

12. Files with databases (*.dbs) are localized: depending on used interface language they are located in folders en-US and ru-RU respectively

Fixed bugs:

1. An incorrect assignment of a seismic category to piping elements generated by automatic FE meshing has been fixed

2. Fixed a bug that caused the program to crash when copying a section containing an angle valve with different sections

3. The command “Files/Make Archive” has been fixed for files containing dot in the file name

4. The output of maximal accelerations of the valve’s body and actuator has been fixed for the case of several dynamic load cases: the maximum values along all sets of excitations are printed out.

5. The requirement to define R2 parameter for branch connections is no more mandatory: in case of its omitting corresponding SIFs are defined as twice greater. See note 9 to ASME NCD-3673.2(b)-2

6. The additional checks for TR and TB parameters of the standard tees are added: TR < DR/2 and TB < DB/2

7. The function of saving changes while editing data in DDE pivot tables of piping supports is restored

8. The following error has been detected and fixed: the values of the corrosion allowances for bends and reducers were taken from the last preceding straight pipe element (this problem is relevant for use of EN-2020 Code.

9. Printout of friction force for restraints defined in the global coordinate system has been fixed

10. The option for simplified fatigue procedure (FATG_SAF='YES') is no more acceptable for High Energy Lines Break (HELB) calculations. This limitation is relevant for PNAE Code analyses.

11. Calculation of thermal stresses due to gross structural or material discontinuity has been fixed (applicable for PNAE or ASME NB analyses)

12. Dimension of moments in the database with allowable loads on supports (sup_lds.dbs file) for the TITAN-2 catalog (TITAN-2_R1_7) is fixed

13. Functionality for viewing animation of the dynamic piping motion in PIPE3DV is restored

14. PIPE3DV: viewing of the one-component restraint located on the vertical piping run and defined in the local coordinate system has been fixed

15. PIPE3DV: a number of decimal digits may be increased in the results tables with new option added in settings, (watch video ).

16. PIPE3DV: option for the gradient coloring is added for viewing piping deflections, (watch video )

17. PIPE3DV: accelerations printout is added in the window activated by “Node info…” command. Spreadsheet view is also available (CTRL-R), (watch video ).

18. PIPE3DV: defects of the displaying stresses in half-opaque elements and rendering of bends in the "wire" model mode are fixed.

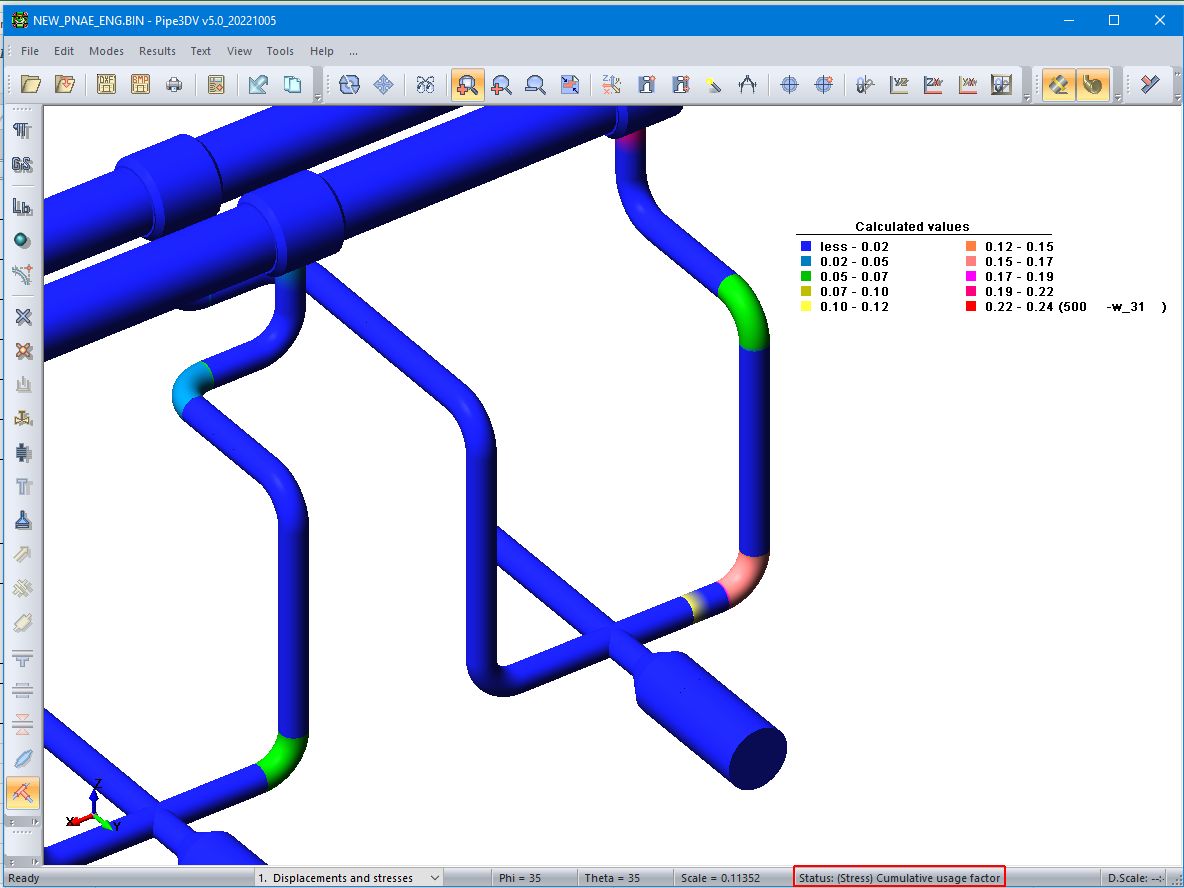

19. PIPE3DV: the view of cumulative usage factor distributed along pipe is fixed (the color scale has been adjusted):

dPIPE Utilities

CVSpec-TH:

loss of accuracy during exporting time-history data in the external file (*.dat) has been fixed: more digits added in the column with time values

Software system dPIPE

Software system dPIPE